When assessing the effectiveness of a sterilization process, calculating the lethality using the F0 method is crucial. One significant consideration in this calculation is the duration required to eliminate a specific number of microorganisms, which can be expressed in either minutes or seconds. Using expressing time in minutes is more widely accepted and practical, understanding the differences and implications of using seconds is also important in certain scenarios. In this blog post, we'll explore the significance of expressing time in minutes or seconds when calculating lethality using the F0 method.

Expressing Time in Minutes

Lethality is the ratio of time required at base temperature to the time required at the measured product temperature to achieve the same total effective reduction of the microbiological population. Expressing time in minutes is the most common practice. It offers several advantages, such as wider acceptance and ease of understanding.

When using minutes, the formula for calculating the F0 value is as follows:

In Kaye software, F0 is calculated as accumulated Lethality, which is the sum of the Instantaneous Lethality (Ileth) values over a selected period of time. The Accumulated Lethality formula accounts for a change in temperature by averaging the current Ileth and previous Ileth values. The data storage rate for a Qualification study should be as small as possible so that the Lethality calculation can account for any change in temperature.

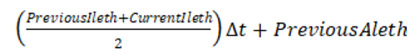

Accumulated Lethality (F0) =

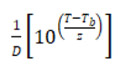

The Instantaneous Lethality (Ileth) formula is shown below.

Instantaneous Lethality =

Where:

D is the time required to reduce microbiological population by 90% (D = 1)

Z is the temperature difference required to change the D value by a factor of 10

T is the product temperature

Tb is the temperature at which the D value is determined (base temperature)

Δt is found by dividing the number of seconds between samples by 60 seconds

Expressing Time in Seconds

While expressing time in seconds is less prevalent, it can be useful in specific situations where the sterilization process is very short. By using seconds, the F0 value can be more conveniently rounded to a whole number. To calculate the F0 value in seconds, the formula is modified as follows:

Accumulated Lethality (F0) = x60

Multiplication by sixty converts the time from minutes to seconds.

Understanding the Implications

It's crucial to note that the choice between expressing time in minutes or seconds does not impact the outcome of the calculations. However, it does influence the clarity of the results and the unit of measurement used. When deciding how to express time, professionals should adhere to the standards and guidelines specific to their industry or sterilization process.

To illustrate the practical application, let's consider a scenario using the F0 method in minutes. Assume a product exposed to steam at 121°C (250°F) for 60 minutes. The initial temperature is 20°C (68°F), and the initial microorganism count is 1x10^6. After sterilization, the remaining microorganism count is 1x10^3.

Using the formula above, the calculated F0 value is approximately 44 minutes.

Now, let's explore the same scenario but express time in seconds. Using the modified formula, the F0 value is approximately 2640 seconds which is equivalent to 44 minutes, but calculating with seconds gives a more precise time value, while providing the sample rate is set accordingly.

Conclusion

It's important to remember that these are simplified examples, in a real-world scenario there could be multiple variables that need to be considered to get a more accurate result. Also, in real-world calculations, the logarithms should be calculated with appropriate software or a calculator.

Keep in mind that the F0 value should be determined according to the sterilization process, the product, and the microorganisms involved. The F0 value is commonly used as a benchmark to compare the effectiveness of different sterilization processes and to ensure that a sterilization process has met the desired level of sterilization.

Copyright: Amphenol Corporation