Warehouse mapping is defined by regulatory guidelines as a seasonal requirement to ensure that storage conditions are maintained at defined specifications. This is a very critical step in ensuring your products and assets are kept safe and within the threshold of standards while stored in your facility. A bi-annual thermal mapping can keep your facility in compliance and ensure products are kept safe.

Challenges

Throughout a calendar year the temperature swings outside can cause products and assets inside your facility to change in temperature or humidity. Oftentimes, even small temperature swings can ruin sensitive assets and increase the risk of losing product. That’s why it’s important to perform a warehouse mapping using equipment that is built to withstand and detect any type of temperature change inside your facility.

Winter and summer warehouse mapping is defined by regulatory guidelines to ensure that storage conditions are maintained at defined specifications.

Critical parameters involve the measurement of temperature and humidity to ensure the uniformity and control of the warehouse.

Solutions

At least twice per year, usually once in the winter and once in the summer, it’s important to protect your temperature and humidity-sensitive products by performing a thermal warehouse mapping of your storage, chambers, freezers, refrigerators, or warehouse.

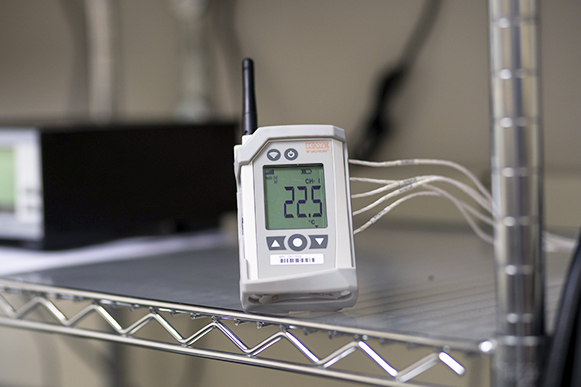

This mapping can be done with wireless data loggers that are placed throughout the facility or inside a chamber and continuously monitor the environment. The data is then collected through an intuitive software that displays the data in an easy-to-read program.

Benefits of a thermal mapping

1. Identify and know your environment

Any perishable asset, especially ones that are sensitive to temperature/humidity, is at risk of being spoiled with a shift in the environment. Whether it be pharmaceutical assets, medicine, blood banks, vaccines, biotech assets, or the like, it’s vitally important to monitor their storage units to ensure compliance.

2. Foresee areas of risk

Performing a mapping and getting a full understanding of your facility will help identify weak areas or spots that have changed in temp/humidity. This is especially important in areas where there is a lot of foot traffic, opening/closing of doors, thermal envelopes, HVAC systems, direct sunlight, etc.

3. Regulatory Compliance

GMPs require the use of calibrated equipment and calibration records. If you gathered data in electronic form, these records must meet regulations for electronic records as defined in 21 CFR Part 11, in EC Annex 11, and in European Union GMP Volume 4.

Storage units that should be mapped bi-annually

- Cold rooms

- Warehouses

- Stability chambers

- Incubators

- Refrigerators

- Freezers

- Cryogenics

Equipment to use for mapping

It’s important that you use a system with equipment that has robust technology to detect even the slightest changes.

The Kaye RF ValProbe®II wireless data logger integrates breakthrough RF Mesh technology with enhanced technology for Thermal Validation. The operating range of the loggers is -40°C to 60°C and the temperature sensor range of -200°C to 200°C, making them ideal for real-time RF validation and monitoring of environmental chambers, warehouses, freezers, refrigerators and steam-in-place (SIP) applications.

The RF ValProbe's will continuously monitor your facility's temperature and give you an instant readout, making it simple for you to understand your site's conditions. During a warehouse mapping, the probes can be easily placed throughout the facility and read using our intuitive software on any PC or smartphone.

View Kaye’s rental solutions here to find which products will work best when doing a warehouse mapping of your facility.