The calibration of the systems and sensors currently in use, along with the complete elimination of identified deviations, constitute fundamental components of a qualification. These are essential for the subsequent validation of a critical process within a GxP context.

As we know, the steps of a standards-compliant validation of a thermal process can be broken down into four key fundamental steps:

- Step 1: Calibration and adjustment of the temperature sensors used

- Step 2: Placement of the sensors in the unit to be validated and data acquisition

- Step 3: Removal of the temperature sensors and, depending on the type of sensor,

checking the calibration and adjustment through a post-calibration - Step 4: Analysis of the collected measurement data and standards-compliant

preparation and documentation of all calibration and measurement protocols

In Part 1 of this blog series, we delved into the history of Kaye and its development into a market leader in the field of thermal validation. Part 2 focuses more extensively on Step 1: the calibration and adjustment of the temperature sensors used. For this, the heat source for temperature calibration is a crucial component.

Although scientific literature talks extensively about the subject of calibration of temperature sensors, specifications, permissible deviations, and possible sources of error, we want to raise awareness around some basic points in this blog post. We hope this encourages a deeper understanding of one's own knowledge.

What potential heat sources (temperature calibrators) are available?

Considering the available heat sources (temperature calibrators), two different types have established themselves in validation practice:

- Block calibrators (Calibration ovens)

- Calibration baths (Liquid calibration baths)

Both systems are used. However, one should be aware of the respective design-related characteristics to ensure that the subsequent calibration also delivers the desired results. In the course of this blog post, we will discuss some fundamental differences and potential errors to watch out for.

The Kaye Block Calibrators

Almost simultaneously with the introduction of the first Kaye Validator Digistrip I, Kaye was not just concerned with fast, thermoelement-based data collection. The company also provided the equipment for a perfect calibration: the calibration units.

The Kaye HTR-300 was the first calibration unit specifically designed for the calibration of thermocouples. Appropriate structural measures, namely special use sleeves, were used to ensure that measurement errors were minimized. These sleeves fit the diameter of the thermocouples to be calibrated and thus reduce potential measurement errors due to the temperature transition between the sensor and the heat source. Further possible sources of error, especially when calibrating sensors in block calibrators, will be discussed later.

Strictly speaking, the Kaye HTR-300 was a hybrid between a calibration bath and a block calibrator. Its high temperature stability was based on the use of calibration oil in the double wall of the calibration body. This gave him the advantage that the sensors to be calibrated did not come into contact with the calibration bath medium and were not wetted with silicone oil.

The relatively high weight and the invariably slow heating and cooling rates of liquid baths were certainly disadvantageous at this point. Therefore, more time had to be planned when calibrating several measuring points for the adjustment.

True to Kaye's in-house philosophy of providing better and more optimal solutions, the further development of the block calibrators available since the 1960s was then advanced with a particular focus on optimizing these devices for the needs of thermocouple calibration.

The Kaye HTR and LTR product family has undergone remarkable developments in the last 20 years. The Kaye HTR-400 and the Kaye LTR-140 block calibrator were the first portable calibration units of this series and quickly established themselves as the industry standard.

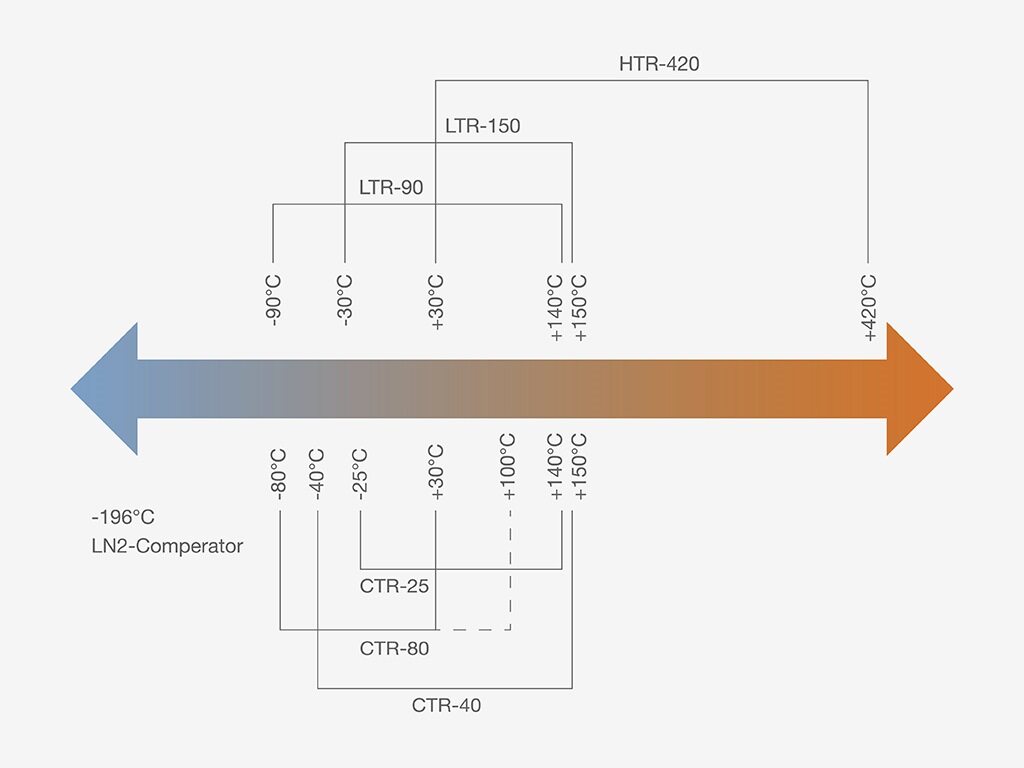

To extend the temperature range, especially for applications below -25°C, the Kaye LTR-40 and almost simultaneously the Kaye LTR-90 were added to the product line. These units enabled temperatures to be reduced to -90°C. Only a few years later, the Kaye HTR-420 extended the temperature range up to +420°C. The range from -30°C to +150°C can be covered by the Kaye LTR-150. In addition, the LTR-150 also offers the additional option of being converted into a liquid bath calibrator, or to be configured for surface temperature calibration.

After the temperature range had been extended, the next focus was on increasing the number of sensors that could be calibrated simultaneously. While the LTR-140 was limited to a maximum of 18 sensors per calibration run, the HTR-400 could only calibrate a maximum of 24 sensors due to design-related restrictions.

The current state of technology allows for parallel and simultaneous calibration of a total of 48 thermocouples. This is possible with both the Kaye LTR-150 and the Kaye HTR-420 block calibrator. With the LTR-90, the number of thermocouples that could be calibrated simultaneously was increased from originally 12 to 16 and later even to 25. This was achieved through special inserts only available from Kaye. An important prerequisite here is that the temperature distribution in the calibration block itself and the stability of the entire calibration unit are not negatively influenced by these special Kaye inserts. This ensures that, regardless of the user, an optimal temperature transition between the sensor to be calibrated and the block calibrator can be guaranteed.

The entire range is further optimized and supplemented by a variety of practical additional options. Specialized, interchangeable thermocouple inserts to increase flexibility in use and a thermocouple holder only available from Kaye round off the product range. It is particularly noteworthy that Kaye, as the first system supplier, enables automatic calibration and adjustment of the thermocouples through appropriate software modules. The Kaye IRTD-400 is used as a traceable temperature standard between the actual data logger and the connected calibration unit.

All listed block calibrators can of course be directly connected to the Validator AVS. They are backward compatible with the predecessor model, the Kaye Validator 2000, as well as with the Kaye ValProbe RT and Kaye ValProbe data logger systems. Thus, they enable the realization of automatic calibration and adjustment of the sensor elements.

Kaye Calibration Baths

Following the expansion of its product range with battery-operated data loggers, with and without real-time data transmission, Kaye continued to pursue the principle of automatic calibration and adjustment of sensors. This principle includes linking the sensors to the respective calibration unit, a traceable temperature standard, and the associated evaluation unit. In the early 2000s, when the first Kaye data loggers were introduced, the product range was also supplemented by appropriate calibration baths.

For flexible or bendable temperature sensors, calibration in a block calibrator (Dry Well Oven) is possible. However, a precise and error-minimized calibration, depending on the form factor and sensor length, can be realized exclusively in a liquid bath. Especially with battery-operated data loggers, the highest level of achievable measurement uncertainty is given when the sensor and evaluation electronics are calibrated at the same temperature. This means that both the sensor and the data logger are calibrated together in the calibration bath. This serves to minimize errors due to the temperature coefficient of the evaluation electronics.

The Kaye Calibration baths CTR-25, CTR-40, and CTR-80 cover a temperature range from -80°C to +140°C. The Kaye LN2 Comparator is used for calibration under liquid nitrogen (-196°C).

Temperature coverage by Kaye Dry-Block Calibrators and Calibration Baths

What are the fundamental differences between a Kaye Block Calibrator and a Kaye Liquid Calibration Bath?

In addition to obvious differences, such as portability, cleaning effort, and speed of temperature change, the capacity and the maximum number of sensors to be calibrated at the same time, and the possible temperature range, the following criteria should be considered when choosing the right calibration unit:

- Axial and radial homogeneity of temperature (temperature distribution)

- Errors during loading / heat output / heat transfer

- Temperature stability

- Stabilization time

- Hysteresis

- Influence of ambient temperature

- In liquid baths, the chemical properties of the calibration medium also play a role. This includes temperature range, ageing, off gassing, and hygroscopic properties

- Also, with calibration baths, the possible contamination and subsequent cleaning of the sensor to be calibrated by the bath fluid should be considered

Of course, all of these mentioned sources of error have already been taken into account in the design and development of Kaye block calibrators and calibration baths, according to the "Quality by Design" principle. Often, despite the precision and accuracy of the devices, the user can be one of the greatest remaining sources of error. Yet, precisely for such cases, Kaye provides a global network of specialists. These experts can conduct practical user training sessions to ensure that the equipment is operated in the best possible manner and that potential user-related errors are avoided.

This representation of the development of block calibrators and calibration baths at Kaye, in connection with the technical advances, is evidence of the company's continuous innovation. It shows commitment to providing practical and optimal solutions in the field of thermal process validation in the GxP environment. With groundbreaking technologies and solution-based approaches, Kaye assumes a leading market position and symbolizes sustainable innovation power.

To enquire about a product or service, you can reach out to us online and one of our representatives will be happy to assist you! To contact us, please visit us here: https://www.kayeinstruments.com/en/contact

To request a demo of any of our products, please visit our demo request website here: https://www.kayeinstruments.com/en/demo

Follow us on LinkedIn or register for our newsletter: https://www.kayeinstruments.com/en/newsletter-subscription

Copyright: Amphenol Corporation