Unlike your car, validation and calibration equipment don’t necessarily need an oil change or their tires rotated, but there are important preventative steps you can take to help extend the life of your instruments and minimize risks for your Validation studies.

1. Avoid Getting Moisture into the SIMS

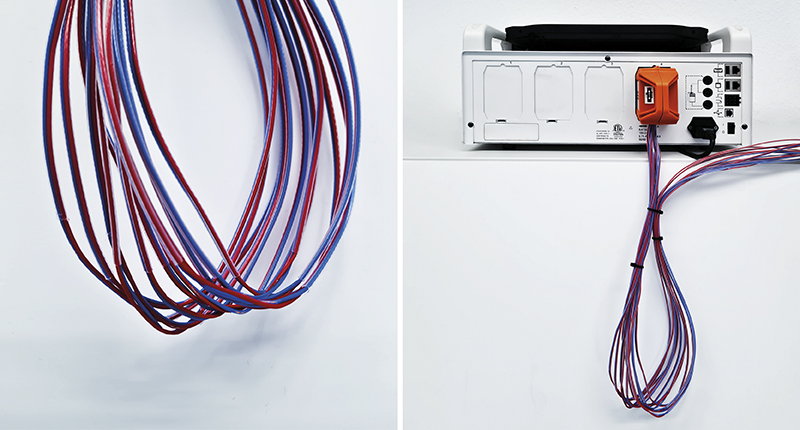

When performing validation studies on a pressurized steam sterilizer, with an AVS or Validator 2000, there are extra precautions which need to be taken to avoid moisture wicking up the thermocouple wires into the SIM. Kaye thermocouple wires are constructed with an inner Teflon sleeve covering each wire (red & blue) as well as an outer clear Teflon coating covering both wires. When ordered as a probe, the Kaye thermocouples also include a welded tip which is covered with a Teflon heat shrink tubing to protect the tip and to prevent moisture from wicking up the wire from the inner and outer sleeving. If you purchase spools of wire and make your own tips you should always order the thermocouple tip kit which include the Teflon shrink tubing to make your own tips. Using bare tip wires without the tip is the cause of 90% of the water which can wick up to the Sim. Water in the Sim can affect the cold junction readings as well as harm electronics and corrode the terminal strips.

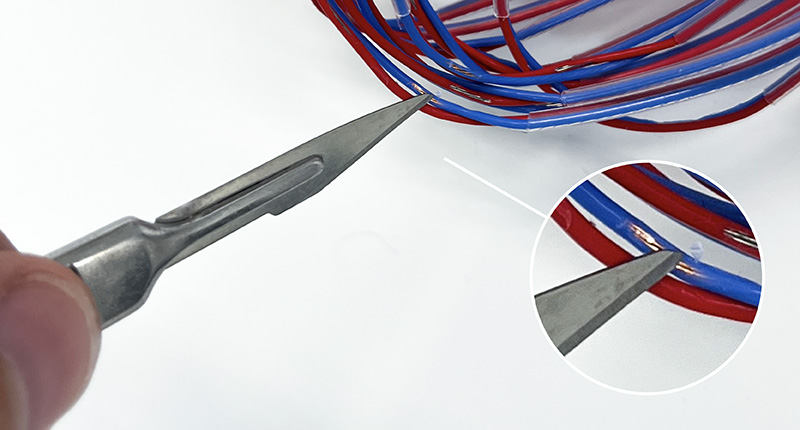

Even with a proper tip the outer Teflon tip is slightly porous or could be damaged or cut during normal use. In this case many customers utilize what is called a drip cut in the wire to avoid any moisture.

To add a drip cut remove 4 inches(10cm) off the outer insulation from each thermocouple at a point where natural drainage can take place without water reaching the SIM. Also, it is recommended to shave open approximately ¼ inch from each of the inner wire jackets at opposite ends of the outer insulation drip cut. This permit condensation drainage from within the individual wires.

Of course, the easiest way to avoid moisture wicking for steam sterilizers is to use the new Kaye Autobond thermocouple wire which is designed specifically to eliminate wicking of water in the thermocouple probes.

The Autobond design eliminates the outer coating which is where 90% of the wicking occurs. This inner coating is more of a mold which fills any air gaps inside the TC, thus blocking any moisture from creeping in.

2. Connection of SIMS

SIMS should always be inserted into the AVS or Validator 2000 prior to turning on the unit. This is to ensure they will be properly read.

Conversely don’t hot swap the SIMS – that is, don’t pull a SIM out while the AVS is currently on. Always power down the AVS first.

Do not force them into the AVS. SIMs were meticulously designed to fit perfectly inside each port – simply lift up slightly and ensure it is lined up with the slot.

3. Proper Care Of Your IRTD

The IRTD is a secondary high precision standard which is the heart of the validation system. The traceability and accuracy of all your temperature measurements relies on the stability and accuracy of the IRTD (+/- 0.025 C). Therefore, they should be properly handled to avoid damage.

While it is true that an IRTD is designed to be a rugged piece of equipment, it still must be handled with care. Any kind of bumps or impacts can cause damage. And damage will affect the functionality of your IRTD.

It turns out that some users don’t properly remove the IRTD before transporting their dry block calibrators. The handles on the Kaye HTR-400, LTR-40/140, and LTR-25-140 were designed with a handle that swings 180 degrees for easy handling. Well, when an IRTD is left inside the dry well and the dry well is picked up by the handle, it can swing forward and bend the IRTD.

Always ensure that you safely remove your IRTD before moving a dry block calibrator. This will ensure that the IRTD isn’t given the chance to bend and will guarantee a longer life and accuracy of your temperature standard.

Here’s some more free advice regarding your IRTD.

- When inserting it into a temperature reference block, don’t drop it and let it hit the bottom of the well. Make sure you hold onto it and slowly insert it into the well completely. Dropping it can damage the sensor.

- When sending an IRTD back to the Kaye lab for an annual calibration, ensure you wrap it completely, or put it in a hard case with foam, so it’s protected inside the shipping box. The sharp point of the IRTD can easily poke through a shipping box during transit when not properly protected.

4. Proper Disconnection of Validation Console

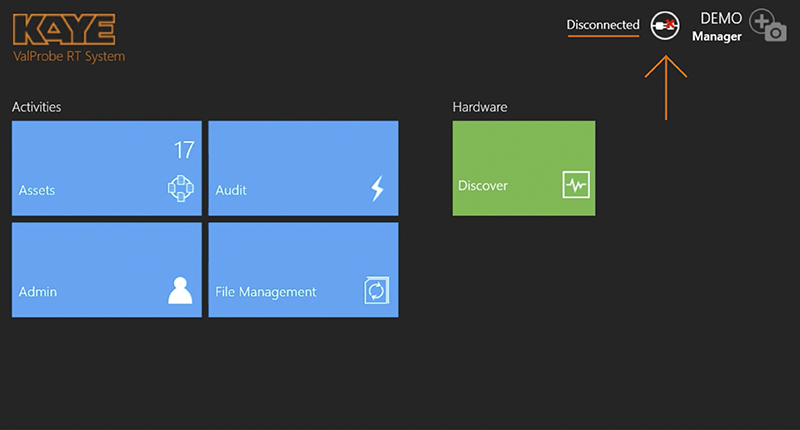

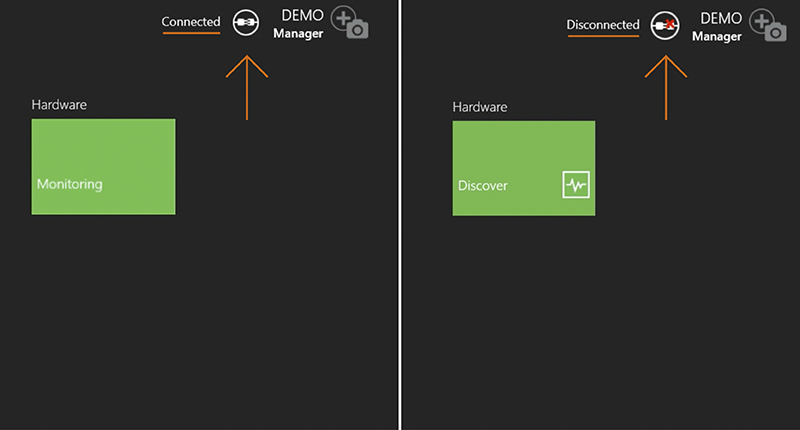

A single Kaye Validation Console is compatible with multiple AVS units, so you’re able to take it off of one AVS and easily put it on another. However, you must first ensure that you properly disconnect it from one AVS before connecting it to the next.

It’s sort of like when you have a USB flash drive plugged into your computer. You can’t just yank it out – it could damage the information that’s on it. You have to first safely eject the device and wait for your computer to prompt you that it’s safe to remove it.

In a similar way, you need to make sure you disconnect your Validation Console from the AVS before detaching it from the base. This can be done by pressing the “Connect/Disconnect” button on the top right corner of the Console screen.

Then wait for the green light indicator on the front of your AVS base to go out – this means it’s safe to undock the console.

Copyright: Amphenol Corporation