GxP Dictionary

A

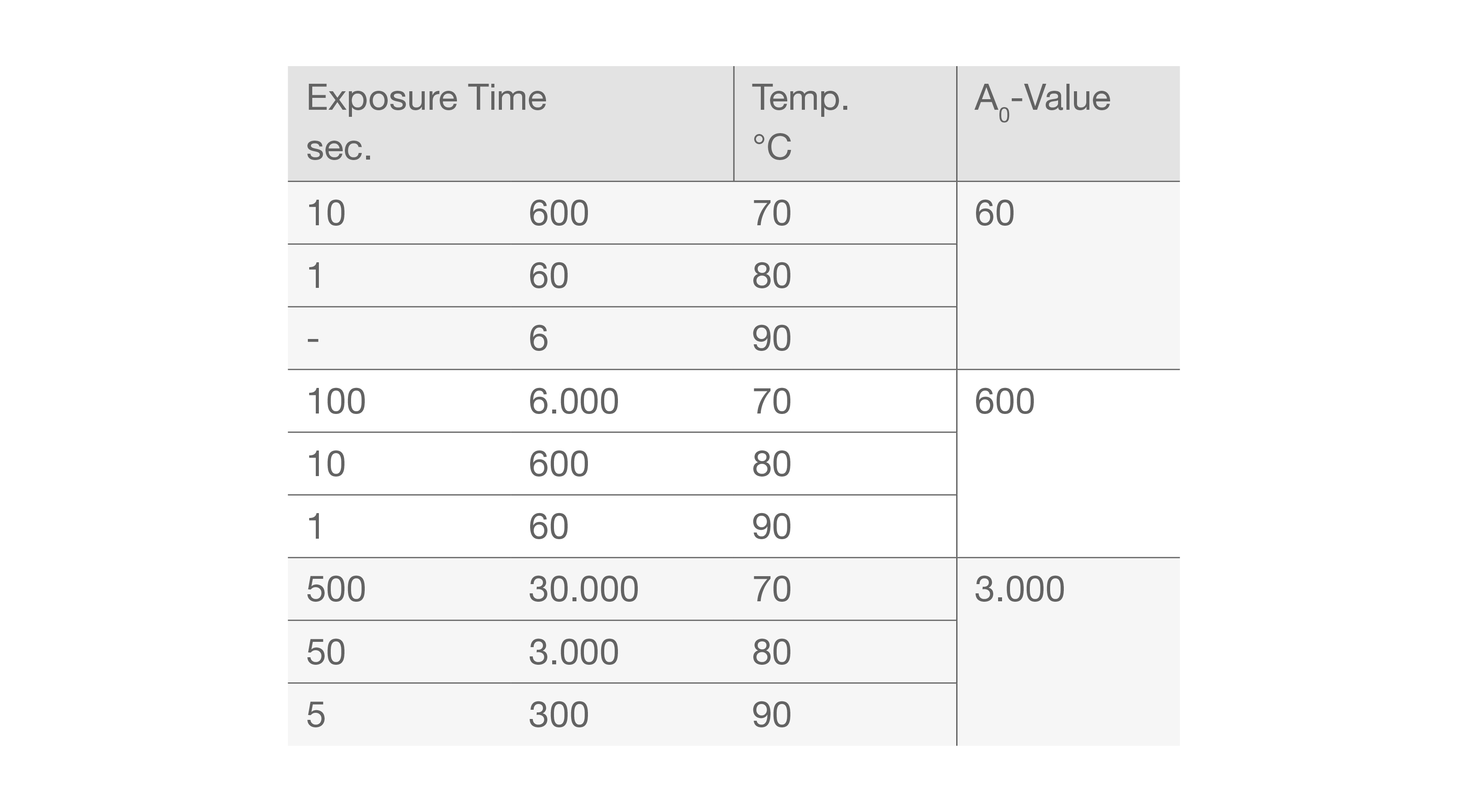

A0-Value

A

ALCOA (++) Principle

A

Annex 1

A

API – Active Pharmaceutical Ingredient

A

APR – Annual Product Review

A

Audit

A

Audit Trail

B

Bioburden

B

BP – British Pharmacopoeia

C

21 CFR – Code of Federal Regulations

C

21 CFR part11

C

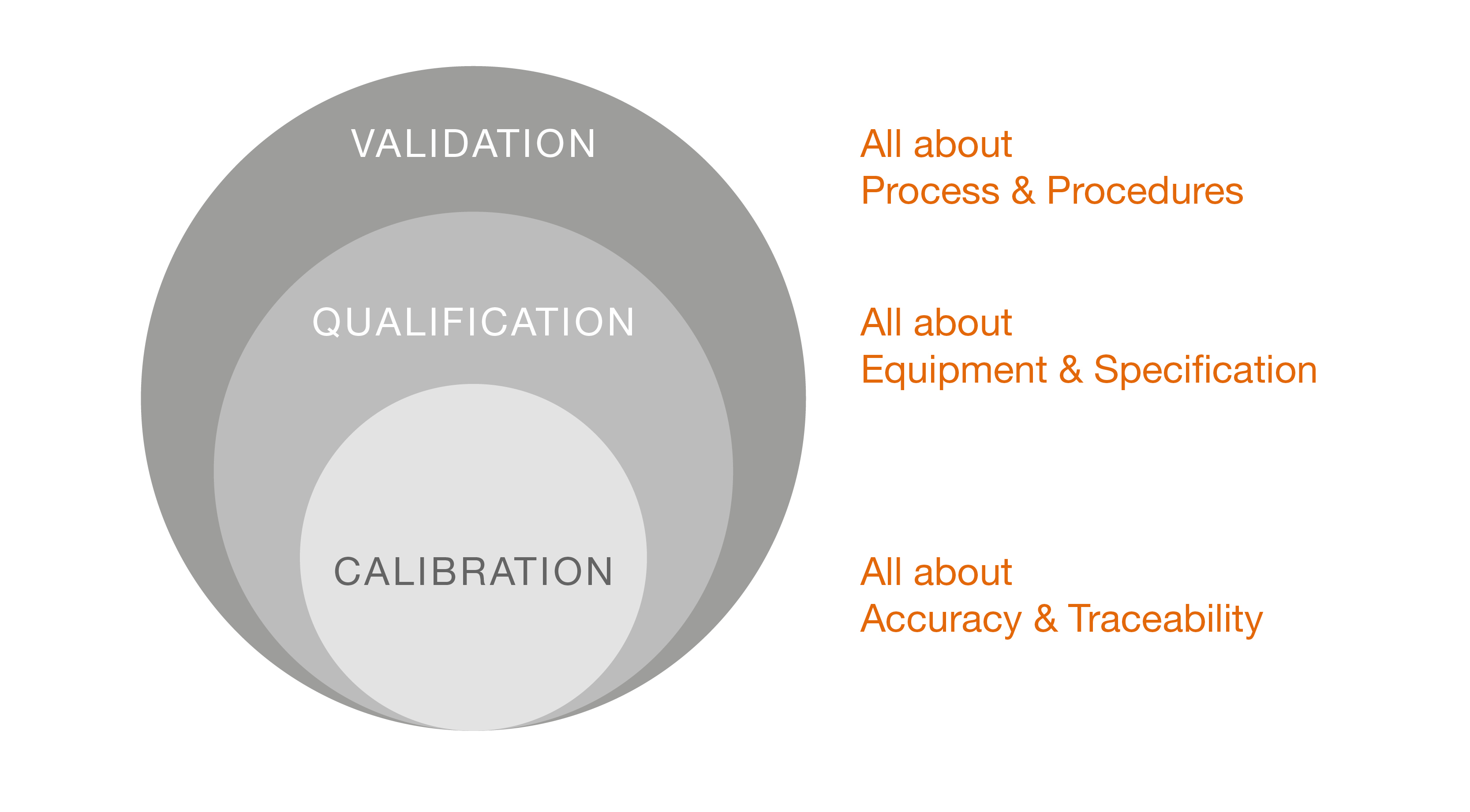

Calibration

C

Calibration Protocol

C

CAPA – Corrective and Preventive Action

C

CC – Change Control

C

CFR – Code Federal Regulations

C

CFU – Colony Forming Unit

C

ChP – Chinese Pharmacopoeia

C

CIP – Clean in Place

C

Cold Chain

C

Cold Chain Management

C

Compliance

C

Concurrent Validation

C

CPV – Continued Process Validation

C

CQA – Critical Quality Attributes

C

CSV – Computer-System/ -Software-Validation

D

D-Value

D

Data Integrity

D

Design Specifications

D

Deviation

D

Deviation Management

D

DMS – Document Management System

D

DQ – Design Qualification

E

EMA – European Medicines Agency

E

EP – or Ph.Eur European Pharmacopeia

E

EU-GMP – Annex

E

EU-GMP Annex 11 – Computerized Systems

E

EU-GMP Annex 15 – Qualification and Validation

E

EU-GMP Annex 20 – Quality Risk Management (QRM)

E

EU-GMP Guidelines

F

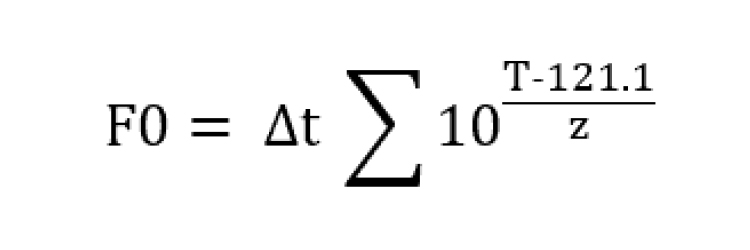

F0-Value

F

FAT – Factory-Acceptance-Test

F

FDA – 482

F

FDA – 483

F

FDA – Food and Drug Administration

F

FDA – Warning Letter

F

FDA Guidance for Industry – Process Validation

F

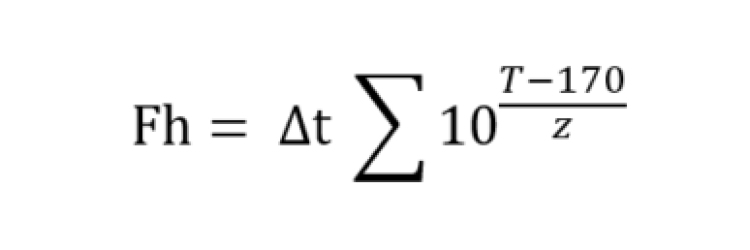

Fh-Value

F

FMEA – Failure Mode and Effects Analysis

F

FMECA – Failure Mode, Effects, and Criticality Analysis

F

FTA – Fault Tree Analysis

G

GAMP® – Good Automated Manufacturing Practice

G

GAMP® 5V-Model

G

GCP – Good Clinical Practice

G

GDP – Good Distribution Practice

G

GEP – Good Engineering Practice

G

GLP – Good Laboratory Practice

G

GMP – Good Manufacturing Practice / cGMP – current Good Manufacturing Practice

G

GSP – Good Storage Practices

G

GxP/ cGxP

H

HACCP – Hazard Analysis and Critical Control Points

H

HAZOP – Hazard and Operability Study

I

ICH – International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use

I

ICH Q9 – Quality Risk Management – Scientific Guideline

I

IQ – Installation Qualification

I

ISPE® – International Society for Pharmaceutical Engineering

I

ISPE® GAMP® 5 – A Risk-Based Approach to Compliant GxP Computerized Systems

J

JP – Japanese Pharmacopeia

L

LVP – Large Volume Parenteral

O

OOE – Out-of-Expectation

O

OOS – Out-of-Specification

O

OOT – Out-of-Trend

O

OQ – Operational Qualification

P

PAT – Process Analytical Technology

P

PCS – Process Control System

P

PDA® Parenteral Drug Association

P

PHA – Preliminary Hazard Analysis

P

PIC/S® – Pharmaceutical Inspection Cooperation Scheme

P

PPQ – Process Performance Qualification

P

PQ – Performance Qualification

P

PQR – Product Quality Review

P

Predictive Maintenance

P

Preventive Maintenance

P

Prospective Validation or Premarket Validation

P

PS – Purified Steam

P

PV – Process Validation

P

PW – Purified Water

Q

QA – Quality Assurance

Q

QbD – Quality-by-Design

Q

QC – Quality Control

Q

QMS – Quality Management System

Q

QP – Qualification Protocol

Q

QP – Qualified Person

Q

QSM – Quality System Manual

Q

Qualification

R

Retrospective Validation

R

Revalidation

R

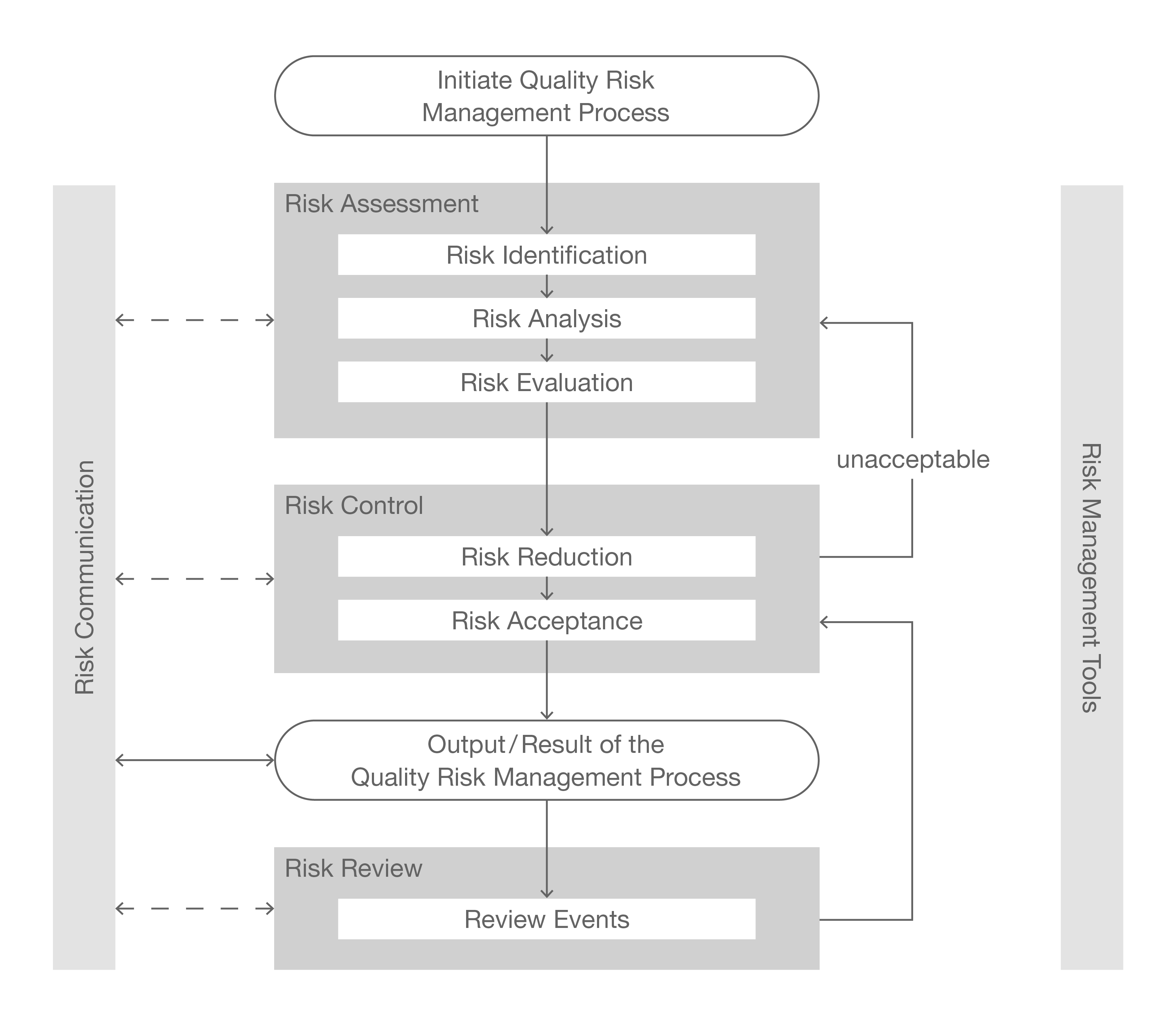

Risk Acceptance

R

Risk Analysis

R

Risk Assessment

R

Risk Communication

R

Risk Control

R

Risk Evaluation

R

Risk Identification

R

Risk Management

R

Risk Management Tools

R

Risk Reduction

R

Risk Review

S

SAL – Sterility Assurance Level

S

Sanitization

S

SAT – Site-Acceptance-Test

S

SIP – Steam in Place

S

SMF – Site Master File

S

SOP – Standard Operation Procedure

S

Steam Quality

S

SVPs – Small Volume Parenteral

T

Temperature (Heat) Penetration Study

T

Temperature Mapping Study

T

Traceability

U

URS – User-Requirements-Specifications

U

USP® – United States Pharmacopeia

V

Validation

V

Validation Matrix

V

Validation Plan

V

Validation Protocol

V

Validation Report

V

VMP – Validation Master Plan

W

WFI – Water-for-Injection

W

WHO – World Health Organization

W

WIP – Washing-in-Place

Z

Z-Value

Z